Pulsed Laser Deposition

Pulsed Laser Deposition (PLD) is a versatile technique for growing thin films and can be applied to a very wide range of materials.

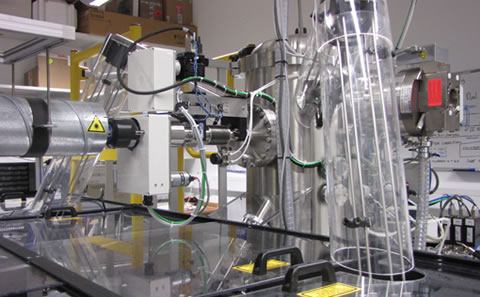

A pulsed laser (usually ultra-violet (UV) wavelength) is used to ablate a target, and a plasma plume is formed by the ejected material, as shown in Fig. 1; the plasma plume then expands away from the target surface and interacts with the chamber atmosphere until it reaches the substrate, where it is deposited as a thin film.

The substrate can be heated, as shown in Fig. 2, to assist with nucleation and allow crystal growth, and a background gas can be used to help control the film composition.

The PLD process covers many different areas of physics and chemistry, and an increasing understanding of what drives the mechanisms behind successful depositions is critical for the continuous improvement of future films and devices. Several deposition parameters must be carefully optimised before high quality films can be produced. A major advantage of the technique is the occurrence of stoichiometric transfer. This allows complex multi-component materials to be grown and has the added benefit that targets can be adapted easily from small pieces of bulk material.

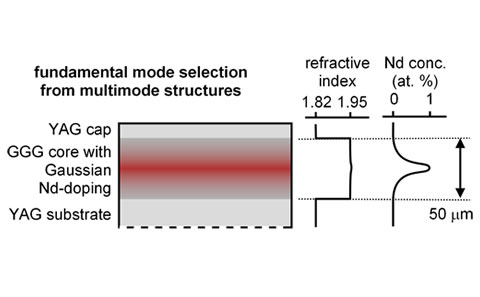

Our work is mainly focussed on the production of high quality optical films for novel laser devices. The thin-film format is ideal for planar waveguide and thin-disk structures, and devices using both of these geometries are currently being pursued.

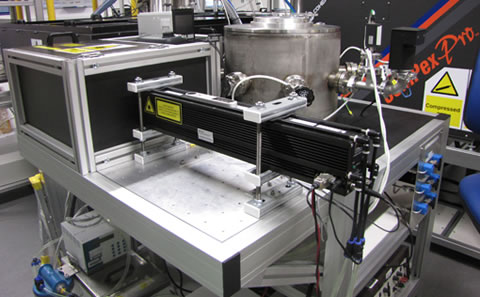

The group operates a state-of-the-art triple-target deposition chamber as shown in Fig. 3(a) and 3(b), and has several lasers and wavelengths available to use on the three different targets (three 266 nm Nd:YAG lasers and an excimer laser capable of operation at 248 nm and 193 nm). The triple target approach allows for some very complex designer structures to be grown, and challenges other film growth techniques to rival it.

Targets can be used sequentially to build up discrete multilayer structures such as superlattices or cladding-pumped designs analogous to cladding pumped fibres.

Alternatively, targets can be used concurrently to make custom crystal compositions, hybrid intermediate compositions, or even to grade composition continuously with depth to make custom refractive index or dopant concentration profiles as shown in Fig. 4. The control and automation of this system is critical for its potential to be fully realised.

PLD offers some unique material deposition capabilities, in particular complex composition film growth and crystal film growth. Some of the group’s work time is spent supplying special films to other groups within the University and externally.

Please see project examples below for more specific details of past, current and future work.

Key research breakthroughs

Listed below are some highlights of key research breakthroughs made throughout the history of the PLD group (most recent first).

Strain engineering of thick garnet crystal films.

- T. C. May-Smith, K. A. Sloyan, R. Gazia, R. W. Eason. Stress engineering and optimisation of thick garnet crystal films grown by pulsed laser deposition. Crystal Growth & Design (accepted) (2011).

Growth of superlattices and mixed garnet crystal layers by dual-beam PLD.

- K. A. Sloyan, T. C. May-Smith, M. N. Zervas, R. W. Eason, S. Huband, D. Walker, P. A. Thomas. Growth of crystalline garnet mixed films superlattices and multilayers for optical applications via shuttered combinatorial pulsed laser deposition. Optics Express Vol. 18 (24) pp.24679-24687 (2010).

Stoichiometry tuned GGG films by dual-beam PLD.

- M. S. B. Darby, T. C. May-Smith, R. W. Eason. Deposition and stoichiometry control of Nd-doped gadolinium gallium garnet thin films by combinatorial pulsed laser deposition using two targets. Applied Physics A: Materials Science and Processing Vol. 93 (2) pp.477-481(2008).

Introduction of a refractive tetra-prism beam homogeniser for CO2 laser substrate heating.

- T. C. May-Smith, A. C. Muir, M. S. B. Darby, R. W. Eason. Design and performance of a ZnSe tetra-prism for homogeneous substrate heating using a CO2 laser for pulsed laser deposition experiments. Applied Optics Vol. 47 (11) pp.1767-1780 (2007).

Growth of multilayer and hybrid layer garnet crystal films.

- R. Gazia, T. C. May-Smith, R. W. Eason. Growth of a hybrid garnet crystal multilayer structure by combinatorial pulsed laser deposition. Journal of Crystal Growth Vol. 310 (16) pp.3848-3853 (2008).

- T. C. May-Smith, D. P. Shepherd, R. W. Eason. Growth of a multilayer garnet crystal double-clad waveguide structure by pulsed laser deposition. Thin Solid Films Vol. 515 pp.7971-7975 (2007).

Growth of a Yb3Al5O12 (YbAG), Y3Ga5O12 (YGG), Nd,Cr:Y3Sc2Al3O12 (Nd,Cr:YSAG), Cr:Gd3Sc2Al3O12 (Cr:GSAG) and Nd,Cr:Gd3Sc2Ga3O12 (Nd,Cr:GSGG) by PLD.

- T. C. May-Smith. Pulsed laser deposition of thick multilayer garnet crystal films for waveguide laser devices. PhD Thesis (April 2005).

Diode-pumped laser operation of a 50 µm thick Nd:GGG film.

- T. C. May-Smith, J. Wang, J. I. Mackenzie, D. P. Shepherd, R. W. Eason. Diode-pumped garnet crystal waveguide structures fabricated by pulsed laser deposition. CLEO/QELS, Long Beach, California, 21-25 May CMFF7 (2006).

Laser operation of rib waveguides based on Ti:sapphire films grown by PLD.

- C. Grivas, D. P. Shepherd, T. C. May-Smith, R. W. Eason, M. Pollnau. Single transverse mode Ti:sapphire rib waveguide laser. Optics Express Vol. 30 pp. 210-215 (2005).

Effect of self-imaging observed in a YAG capped Nd:GGG film.

- T. C. May-Smith, C. Grivas, D. P. Shepherd, M. S. B. Darby, R. W. Eason. Pulsed laser deposition of thick multilayer garnet films for cladding-pumped planar waveguide laser devices. CLEO/IQEC, San Francisco, California, 16-21 May CthE2 (2004).

Ti:sapphire rib waveguides, based on Ti:sapphire films grown by PLD, as fluorescence sources.

- C. Grivas, T. C. May-Smith, D. P. Shepherd, R. W. Eason, M. Pollnau, M. Jelínek. Broadband single transverse-mode fluorescence sources based on ribs fabricated in pulsed laser deposited Ti:sapphire waveguides. Applied Physics A Vol. 79 pp. 1195-8 (2004).

Low loss of 0.1 dBcm-1 observed in a lasing 40 µm thick Nd:GGG film.

- C. Grivas, T. C. May-Smith, D. P. Shepherd, R. W. Eason. Laser operation of a low loss (0.1 dB/cm) Nd:Gd3Ga5O12 thick (40 micron) planar waveguide grown by pulsed laser deposition. Optics Communications Vol. 229 (1-6) pp. 355-61 (2004).

Growth of a 135 µm thick GGG film.

- T. C. May-Smith, C. Grivas, D. P. Shepherd, R. W. Eason, M. J. F. Healy. Thick film growth of high optical quality low loss (0.1dBcm-1) Nd:Gd3Ga5O12 on Y3Al5O12 by pulsed laser deposition. Applied Surface Science Vol. 223 pp. 361-371 (2004).

Characterisation of the effect of particulate density on film loss and laser threshold.

- S. J. Barrington, T. Bhutta, D. P. Shepherd, R. W. Eason. The effect of particulate density on performance of Nd:Gd3Ga5O12 waveguide lasers grown by pulsed laser deposition. Optics Communications Vol. 185 pp. 145-52 (2000).

Establishment of a raster-scanned CO2 laser substrate heating system.

- S. J. Barrington, R. W. Eason. Homogeneous substrate heating using a CO2 laser with feedback, rastering, and temperature monitoring. Review of Scientific Instruments Vol. 71 (11) pp. 4223-5 (2000).

Growth of lead germanate glass.

- S. J. Barrington, S. Mailis, A. A. Anderson, R. Greef, W. S. Brocklesby, H. N. Rutt, R. W. Eason, N. A. Vainos, C. Grivas. UV induced refractive index changes in lead germanate glass waveguides grown by pulsed laser deposition. Photosensitivity in Optical Waveguides and Glasses, Lake Lucerne, Switzerland, 13-18 July (1998).

Laser operation of a Ti:sapphire planar waveguide.

- A. A. Anderson, R. W. Eason, L. M. B. Hickey, M. Jelínek, C. Grivas, D. S. Gill, N. A. Vainos. A Ti:sapphire planar waveguide laser grown by pulsed laser deposition. Optics Letters Vol. 22 (20) pp. 1556-58 (1997).

Low loss of 0.5 dBcm-1 observed in a lasing 8 µm thick Nd:GGG film.

- A. A. Anderson, C. L. Bonner, D. P. Shepherd, R. W. Eason, C. Grivas, D. S. Gill, N. Vainos. Low loss (0.5 dB/cm) Nd:Gd3Ga5O12 waveguide layers grown by pulsed laser deposition. Optics Communications Vol. 144 pp. 183-86 (1997).

Growth of Ti:sapphire crystalline films.

- A. A. Anderson, R. W. Eason, M. Jelínek, L. M. B. Hickey, C. Grivas, C. Fotakis, K. Rogers, D. Lane. Waveguiding and crystallographic properties of single crystal Ti:sapphire layers produced by pulsed laser deposition. CLEO-Europe, Hamburg, Germany, September CTuG8 79 (1996).

Laser operation of a PLD grown Nd:GGG film.

- D. S. Gill, A. A. Anderson, R. W. Eason, T. J. Warburton, D. P. Shepherd. Laser operation of an Nd:Gd3Ga5O12 thin-film optical waveguide fabricated by pulsed laser deposition. Applied Physics Letters Vol. 69 (1996).

Growth of crystalline GGG films.

- D. S. Gill, R. W. Eason, J. Mendiola, P. J. Chandler. Growth of crystalline Gd3Ga5O12 thin-film optical waveguides by pulsed laser deposition. Applied Physics Letters Vol. 25 pp. 36982 (1995).

Growth of crystalline KNbO3 films.

- C. Zaldo, D. S. Gill, R. W. Eason, J. Mendiola, P. J. Chandler. Growth of KNbO3 thin films on MgO by pulsed laser deposition. Applied Physics Letters Vol. 65 (4) pp. 502-504 (1994).

Growth of chalcogenide glass (GLS) films.

- K. E. Youden, T. Grevatt, R. W. Eason, H. N. Rutt, R. S. Deol, G. Wylangowski. Pulsed laser deposition of Ga-La-S chalcogenide glass thin film optical waveguides. Applied Physics Letters Vol. 63 (12) pp. 1601-1603 (1993).

Impact of research

We perform fundamental materials research which is critical for the discovery and development of new and improved optoelectronic materials and devices. We are also pioneering the technique of combinatorial PLD for the fabrication of new and novel structures, aiming to create designer device geometries that no other technique can practically produce. In particular we aim to produce high-power high-efficiency solid-state diode-pumped miniature lasers which may be used in a wide range of applications.

Research facilities

The PLD equipment is housed in a lab in the new Mountbatten Building Fabrication Complex. The PLD equipment consists of two deposition chambers and 6 lasers. A custom-built vacuum chamber (Kurt J. Lesker Company) with a rotating substrate holder and triple target holder with simultaneous rotation and variable tilt control is where the core of our work takes place, as shown in Fig. 3(a). This chamber has a variable speed turbo pump and mass flow controllers for precise control of background pressure with the option of three different gases. Ablating laser pulses can be introduced through 4 different laser windows for use on the three different targets. A 5th laser window allows us to perform raster scanned CO2 laser heating of substrates from the rear while rotating the substrate, aiding homogeneous deposition.

A secondary vacuum chamber, shown in Fig. 5, is setup for thick monolayer deposition using a target holder whose rotation is driven by a cam with a variable off-centre rotation, enabling target surface area to be utilised with very high efficiency for long depositions. This chamber also has a CO2 laser substrate heater, but this time homogenisation is performed using a refractive tetra-prism.

For ablation, we have three frequency quadrupled Nd:YAG lasers and an excimer laser at our disposal. The Nd:YAG lasers emit ~100 mJ pulses at a wavelength of 266 nm (~5 ns, 10 Hz), whereas the excimer laser can emit either 400 mJ pulses at a wavelength of 248 nm or 200 mJ pulses at a wavelength of 193 nm (~20 ns, 20 Hz). This collection of lasers allows us to effectively ablate a range of different materials required for our multilayer and mixing deposition work.

Collaborations

The wealth of fabrication, processing and analysis equipment available within the University makes Southampton a highly rewarding place to do PLD. Interaction with other groups gives us the rare ability to see films through from optimisation and fabrication, all the way to post-processing and device operation. The PLD group interacts with the following:

Internal (ORC and UoS):

Optical Parametric Oscillators Group, led by Professor David Shepherd (ORC). We supply Ti:sapphire films for a new project on miniature mode-locked Ti:sapphire lasers. Interactivity also provides essential skills exchange for waveguide device processing, testing and performance optimisation.

Planar Waveguide and Slab Lasers Group, led by Dr Jacob Mackenzie (ORC). We supply novel structures with advanced multilayers for multi-diode pumping. Evaluation and comparison to other fabrication techniques is done in collaboration with this group. Interactivity also involves initial design and modelling of proposed structures.

Advanced Solid State Sources Group, led by Professor Andy Clarkson (ORC). Interactivity provides essential skills exchange for waveguide and thin-disk device processing, testing and performance optimisation.

Nanophotonics and Metamaterials Group, led by Professor Nikolay Zheludev. We supply magneto-optic Y3Fe5O12 (YIG) films for projects within this group.

Magnetism and Superconductivity Group, led by Professor Peter de Groot. Evaluation of the magnetic properties of YIG films are done in collaboration with this group. We also supply YIG films for their research projects.

Laser-Induced Forward Transfer Group, led by Professor Robert Eason (ORC). We supply films (typically with complex compositions that cannot be deposited easily by other techniques) for laser-induced forward transfer studies.

Novel Glass and Fibre Group, led by Professor Dan Hewak (ORC). The Novel Glass and Fibre Group are greatly interested in the conversion of in-house made bulk glasses into a thin film medium and PLD is an attractive way of achieving this if the long-standing problems with the deposition of glasses can be circumvented.

Infrared Science and Technology Group, led by Professor Harvey Rutt (ORC). The IRST Group have a joint interest in the use of PLD for the deposition of chalcogenide films such as gallium lanthanum sulphide (GLS). Past interactivity has included the growth of zinc sulphide, lead germanate and gallium lanthanum sulphide glass films.

X-Ray Diffraction Facilities, led by Mark Weller and Mark light (School of Chemistry). The X-ray diffractometers are critical for the measurement of crystal lattice constants, assessment of crystal quality and strain.

External:

Laser and Plasma Applications Group, led by Professor James Lunney (Physics Department, Trinity College Dublin). Recent collaboration with the Laser and Plasma Applications Group has been focussed on the differences in plasmas produced by femtosecond and nanosecond ablation, and the possible effects of these differences on crystal and glass film growth.

Work with us

We are always interested to hear from academic groups and industry about potential collaborations. If you are interested in collaborating with us, please contact Professor Rob Eason.

PhD projects with this group:

If you are considering doing a PhD with the ORC, projects within the PLD Group would appeal to those with good problem solving and lab-based skills, as PLD encompasses laser use, surface science diagnostics, modelling, vacuum technology, and device processing and operation. Since our current research activity, and the technique of PLD itself is so diverse, topics can be tailored to an individual’s interests. Visit the PhD pages to find out more about our PhD programme and how to apply.

All photographs taken by and used with permission from Alberto Sposito.

Group members

No members in database.